The tower granulation process is a high-end method in NPK fertilizer production lines, producing round, highly soluble granular fertilizers widely used in field crops. The process is based on the principle of molten slurry spray cooling and requires high-temperature melting equipment and a cooling system. Core equipment includes a melting reactor, spray tower, cooling tower, and screening machine.

Raw material pretreatment equipment, such as hammer mills, crushes phosphates and potassium salts, and a weighing system uses loss-in-weight feeders for precise proportioning. After mixing, the materials enter the melting reactor, heated to 120-150°C to form a uniform slurry, with additives such as ammonium sulfate added to improve fluidity.

The spray tower is crucial, reaching 20-30 meters in height. Nozzles at the top of the tower atomize and spray the slurry, which solidifies into spheres as it falls and comes into contact with cold air. The equipment requires anti-clogging designs, such as vibrating nozzles. The cooling tower uses multi-stage fans to ensure the granule temperature is reduced to ambient temperature, preventing caking.

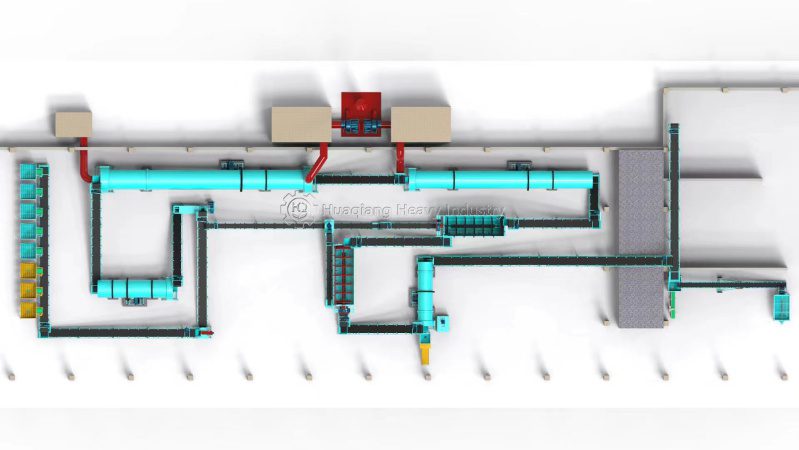

The NPK fertilizer production line process flow is: raw material preparation → melting and mixing → top spraying → air cooling → bottom collection → screening and packaging. Screening equipment, such as rotary screens, removes unqualified granules, which are recycled back to the melting reactor. Drying is completed naturally within the tower without the need for additional furnaces.

Auxiliary equipment includes a waste gas scrubbing tower to treat ammonia and dust, and a heat recovery system that utilizes waste heat to preheat the air, reducing energy consumption by 30%. Automated PLC control monitors temperature and flow rates to ensure safety.

The advantages include good granule appearance and high solubility, making it suitable for water-soluble fertilizer production. One tower-type NPK fertilizer production line can produce over 200 tons per day, with exports to Southeast Asia. In one case study, a European factory used the tower process to produce 20-20-20 NPK, resulting in a 15% increase in crop absorption rate. The integration of tower granulation equipment improves the quality of NPK fertilizer production lines and supports sustainable agriculture.