The batching system is the “core brain” of the NPK fertilizer production line, responsible for achieving precise proportions of nitrogen, phosphorus, potassium, and trace elements. Its process precision directly affects the nutrient content and efficacy of the fertilizer, making it a key equipment system for ensuring stable NPK fertilizer quality.

Process Principle: The NPK fertilizer production line‘s batching system adopts an integrated “weighing-conveyance-mixing” process. Relying on electronic belt scales, screw conveyors, and a PLC control system, it achieves precise metering, uniform conveying, and homogeneous mixing of raw materials. The core logic is based on a preset formula, using sensors to monitor the dosage of each raw material in real time. The signals are transmitted to the PLC control system, which automatically adjusts the conveying speed to ensure that the dosage error of each raw material is controlled within 0.2%.

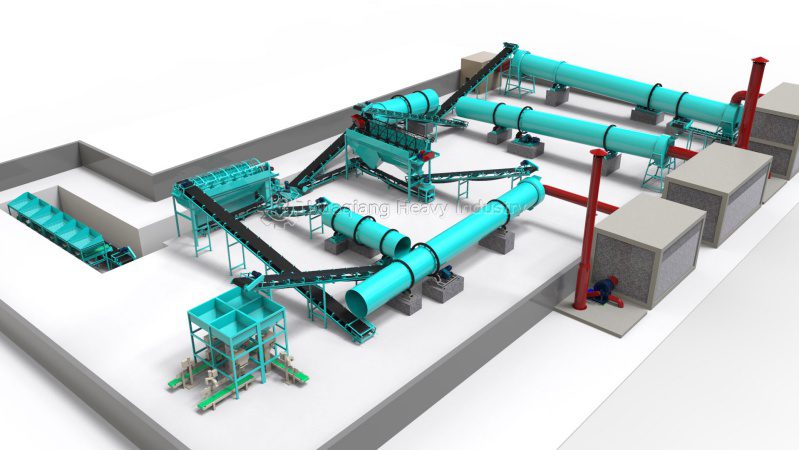

The NPK fertilizer production line‘s batching system mainly consists of a raw material buffer silo, an electronic belt scale, a screw conveyor, a mixer, and a PLC control cabinet. The operation procedure is divided into three steps: Step 1: Formula setting. Input the preset formula (e.g., a 15-15-15 universal formula) into the PLC control cabinet, setting the dosage and conveying speed of each raw material. Step 2: Raw material buffering. Send the pre-treated raw materials into their respective buffer silos, checking the bottom discharge valves for blockages. Step 3: Precise batching. Start the system; the electronic belt scale weighs in real time; the PLC control system automatically adjusts the screw conveyor speed, conveying the various raw materials to the mixer in proportion. The mixer (30 rpm) continuously stirs for 5-10 minutes to ensure uniform mixing before sending to the granulation stage.

Operating Precautions: Before starting the machine, calibrate the electronic belt scale to avoid weighing errors; during operation, observe the parameters in the PLC control cabinet in real time. If raw material feeding deviations occur, manually fine-tune them promptly; after shutdown, clean the conveying pipes and mixer to prevent raw material residue from clumping and affecting the accuracy of subsequent batching. The precise ingredient mixing system allows the nutrient content fluctuations of NPK fertilizers to be controlled within the range allowed by national standards.